How can the effect of metal spraying be improved?

How can the effect of metal spraying be improved?

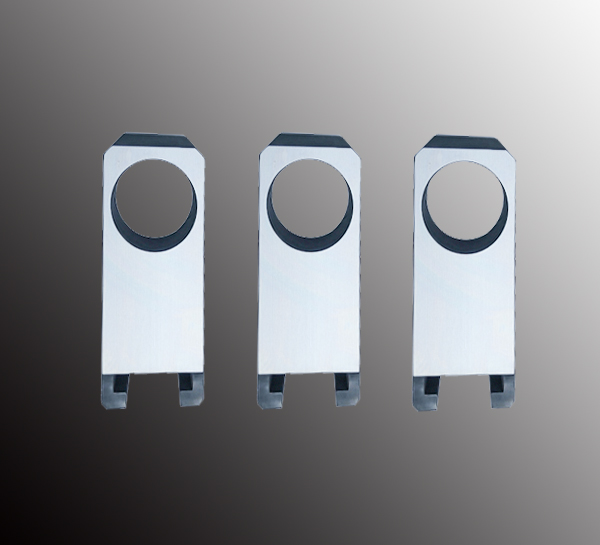

Spraying industry is also an industry that needs to rely on technology relatively. Diversified spraying types have different effects, so in today's fierce market competition, how to improve the effect of metal spraying if you want to occupy a place? Let's have a look. Metal spraying

1. Before spraying metal, it is necessary to clean up the spraying place. No impurities can appear in the spraying process, and the integrity of metal should be ensured.

2. In the process of spraying, only a layer of decoration is carried out for the metal surface, and too thick paint can not be sprayed, which will lead to too thick paint and color deformation, which is not conducive to normal use.

3. When spraying, the uniformity of the paint should be ensured. Before spraying, the paint needs to be stirred, so that the paint can be fully fused, and the upper layer of the paint will not be light, while the lower layer will be turbid.

4. In the process of spraying, if the paint is too viscous, additives can be used in the spraying process, but it needs to be adjusted according to the relevant proportion, so the proportion imbalance can not occur.

In fact, it is important to pay attention in the process of spraying to ensure that the spraying is uniform enough. Can not appear the phenomenon of different thickness, for different thickness of paint, after spraying will affect the overall beauty, resulting in visual disharmony. In the above steps, metal spraying needs technical support before and after, and we should pay special attention to the operation, so what are the unclear aspects? We Jinhu Saiou Electric Co., Ltd. can do guidance for you, welcome to pay attention to us.

15161728000

15161728000 saioudianqi@163.com

saioudianqi@163.com