The advantage of metal spraying is that the equipment is easy to operate

The advantage of metal spraying is that the equipment is easy to operate

The advantage of metal spraying is that the equipment is easy to operate. Why? Let supersonic spray manufacturers Xiaobian tell you

A lot of machines and equipment have complex operation steps, just reading the manual is a headache. But metal spraying will not have such trouble, his simple operation process makes him become a lot of people's internal choice.

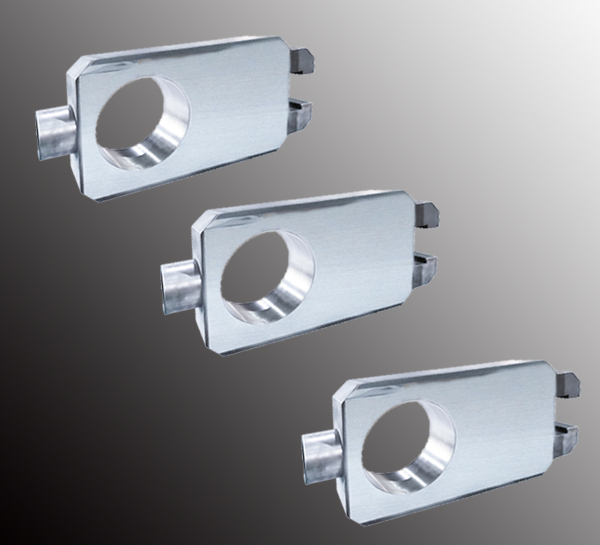

1. In the process of spraying, the heating temperature of the parts does not exceed 70 ~ 80 ℃, so the parts will not produce internal stress and deformation.

2. The thickness of spray coating is much larger than that of electrodeposited coating, up to 10 mm, sometimes up to 15-20 mm. Metal spraying

3. According to the requirements of the spraying layer, the same or different spraying materials can be used as the part materials, and can be sprayed on various metals, plastics, carbon, wood and other materials. After spraying, the wear resistance of steel and iron castings can be improved. Using stainless steel, zinc and aluminum as spraying materials can improve the corrosion resistance of parts, and aluminum can also improve the oxidation resistance and heat resistance. After spraying aluminum and other composite materials, the steel-making electrode can form anti-oxidation coating on the electrode surface, which can resist high temperature and reduce the unit consumption of steel-making electrode.

4. It has low cost and good economic effect. The value of repairing worn parts is only 10-60% of that of new parts according to field data.

5. Spraying equipment and process operation is relatively simple. It is not limited by the shape of parts. After spraying, it can be processed by various mechanical methods.

By looking at the above arrangement, the original metal spraying process not only has the characteristics of simple operation process, spraying layer is much thicker than other spraying equipment, spraying materials also show its diversity

15161728000

15161728000 saioudianqi@163.com

saioudianqi@163.com