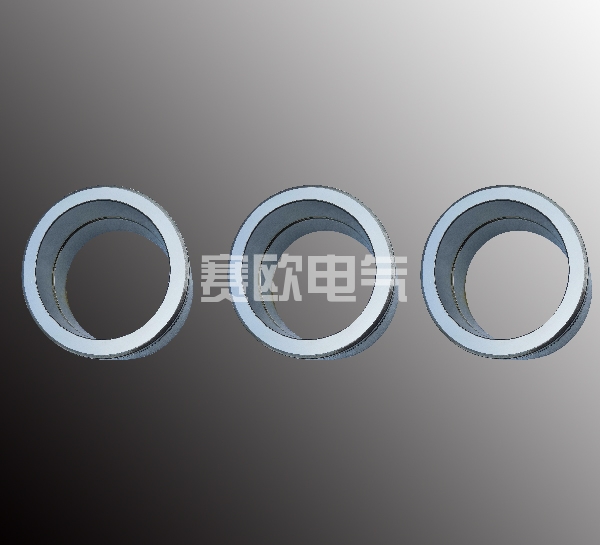

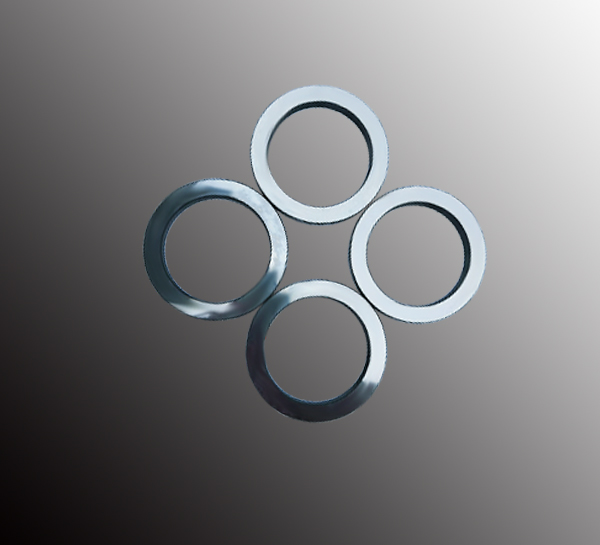

Seat ring

Product attributes

- Classification:阀板、阀座成品

- Product Number:1565425539

- Clicks:0

- Release date:2021-07-09

- Product Overview

- Performance characteristics

- technical parameter

The core components of flat gate valves used in petrochemical industry require high pressure, wear resistance, H2S and CO2 corrosion resistance, especially wellhead Christmas tree valves.

Our company selects high-quality thermal spraying powder as raw material, adopts supersonic spraying equipment, optimizes thermal spraying processing technology, and supports advanced processing equipment and processing technology, so that the coating compactness can meet the requirements of air sealing under 140MPa, and the coating porosity is <: 1%, the bonding strength exceeds 75MPa, the hardness can reach HV1500 and the fluctuation of hardness uniformity does not exceed HV100;;

After coating processing, the surface of the product can reach mirror surface, the roughness is lower than Ra0.1, and the flatness does not exceed 2 light bands, which can effectively reduce the friction coefficient between valve plate and valve seat and prolong its service life.

Process advantages of Jinhu Sail Electric Co., Ltd.:

1. when spraying, the temperature rise of the workpiece is small, which does not affect the matrix structure and change the matrix hardness;

2. Pre-heating or post-welding heat treatment is not needed before and after spraying, which improves the production efficiency;

3. After spraying, it can be directly ground and polished without machining, which improves the efficiency;

4. Using supersonic spraying equipment, by adjusting and controlling various parameters, the bonding strength between coating and substrate is high, the surface hardness of coating is high, the porosity of coating is low, which meets the requirements of API 6A air seal, with small friction resistance, good wear resistance, wear resistance and erosion resistance, and reduces the valve opening and closing torque.

15161728000

15161728000 saioudianqi@163.com

saioudianqi@163.com