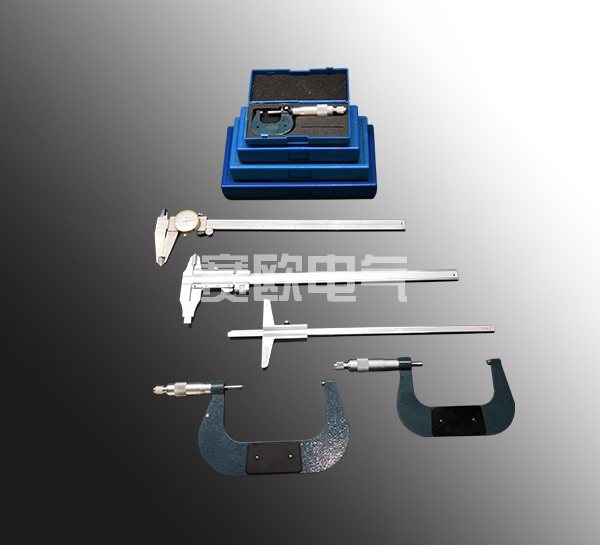

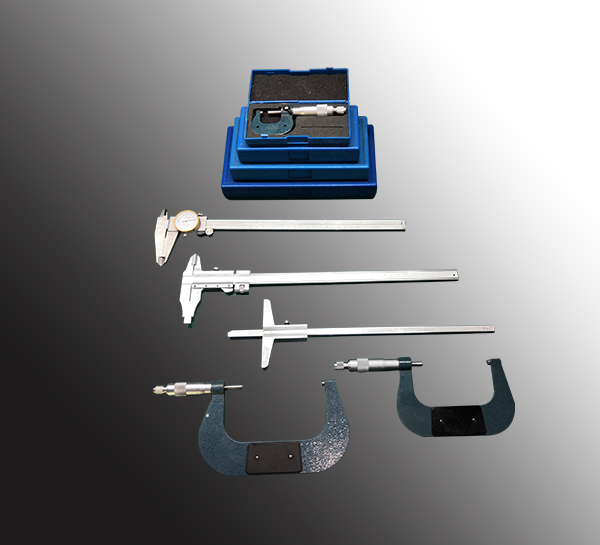

measure

Product attributes

- Classification:检测设备

- Product Number:1564039617

- Clicks:0

- Release date:2021-07-09

- Product Overview

- Performance characteristics

- technical parameter

Ensure that the size of products in the process of processing meet customer requirements

Measuring tool is the abbreviation of physical measuring tool. It is a kind of tool with fixed shape to reproduce or provide quantitative one or more known values.

1、 Preparation before using the measuring tools: (1) before measuring, confirm whether the measuring tools are returned to zero( 2) Check the measuring surface of tools for rust, wear or scratch( 3) First, remove the rough edge, oil or slag on the measuring surface of the workpiece( 4) Wipe with clean soft cloth or dust-free paper( 5) The record book needs to be inspected regularly and corrected again if necessary( 6) The measuring tools and instruments to be used shall be arranged in proper positions and shall not be overlapped( 7) Vulnerable tools should be laid on the worktable with soft flannelette or soft wiping paper (such as optical flat mirror, etc.).

2、 The following points should be paid attention to when using the measuring tools: (1) when measuring, the contact with the workpiece should be appropriate, and it should not be deflected. It is necessary to avoid touching the measuring surface by hand and protect the measuring tools( 2) The measurement stress should be appropriate, too much measurement pressure will produce measurement error, which is easy to damage the work quantity( 3) The clamping mode of workpiece should be appropriate to avoid inaccurate measurement( 4) Do not measure the workpiece in rotation, so as to avoid danger( 5) Do not push the measuring tools into the workpiece or clamp the vise( 6) It is not allowed to knock, throw or work measuring tools at will( 7) The use of special measuring tools should follow certain methods and procedures.

3、 Maintenance of measuring tools after use: (1) they should be clean after use( 2) The cleaned measuring tools shall be coated with antirust oil and stored in the cabinet( 3) Disassembly, adjustment, modification and assembly shall be carried out by special management personnel, not without authorization( 4) The performance of stored tools should be checked regularly, and maintenance records should be made( 5) Regular inspection shall be carried out to check whether the dimensions are qualified, so as to serve as the basis for continued use or elimination, and make a record of inspection and maintenance.

The above is the technical support provided by Saiou Electric Co., Ltd., a metal spraying manufacturer. If necessary, please call us directly.

15161728000

15161728000 saioudianqi@163.com

saioudianqi@163.com